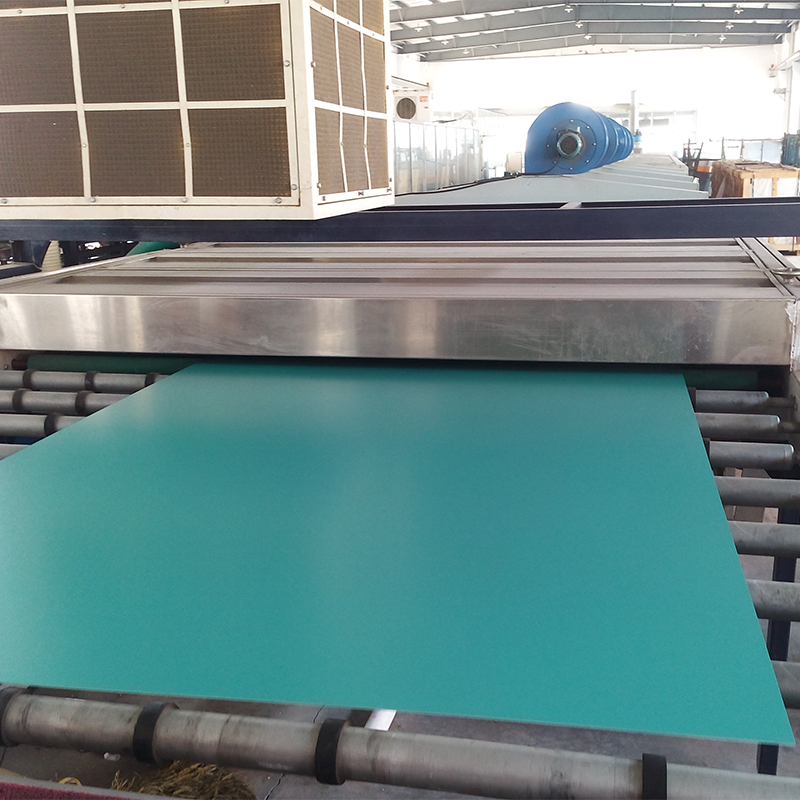

Aluminum mirror glass sheet generally perform well in high-humidity environments, but their performance depends on several factors, such as the quality of the aluminum coating and any protective layers applied. Here's a breakdown:

Corrosion Resistance: Aluminum is naturally resistant to corrosion because it forms a thin oxide layer that protects the underlying metal. However, in very humid conditions, especially with exposure to salt or pollutants, this layer can degrade over time, potentially leading to corrosion or tarnishing if not properly protected.

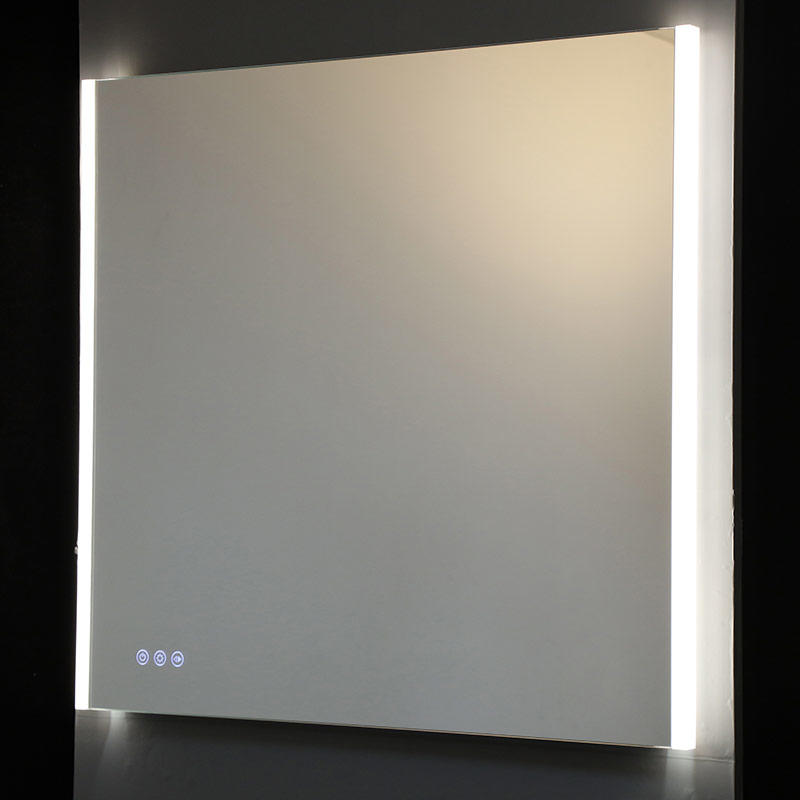

Protective Coatings: Many aluminum mirror glass sheets come with protective coatings or treatments to enhance resistance to humidity and moisture. These coatings can prevent the aluminum from oxidizing and ensure long-term reflectivity.

Durability of Reflective Quality: In humid environments, untreated or low-quality aluminum coatings may lose their reflectivity due to oxidation or water ingress. High-quality sheets with protective finishes will maintain their mirror-like appearance for a longer period.

Condensation Issues: In environments with extreme humidity fluctuations, condensation may form on the surface of the mirror, potentially affecting its clarity. Regular cleaning and maintenance can help prevent moisture buildup.

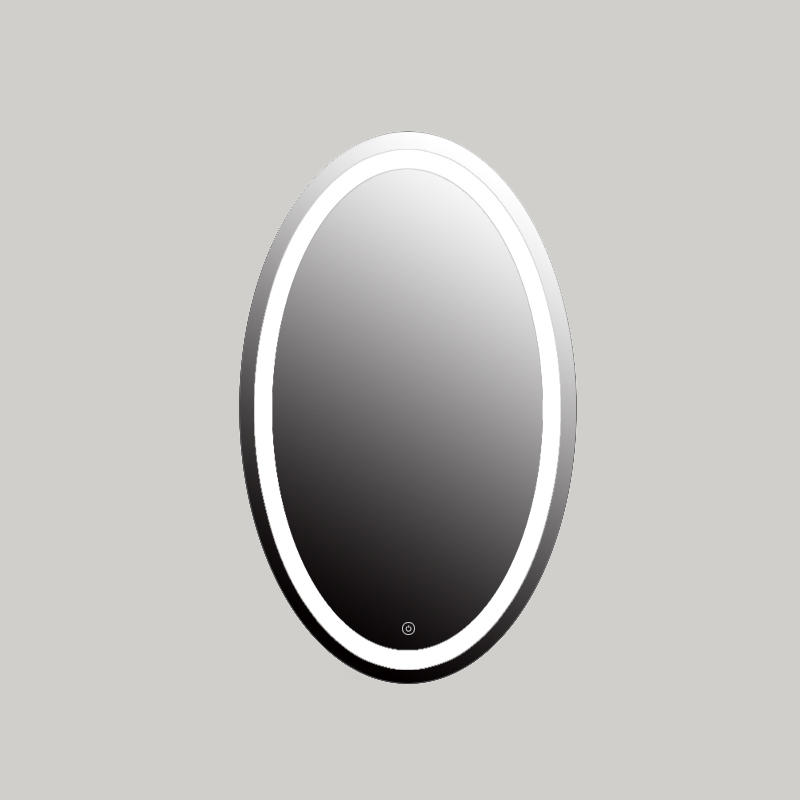

Indoor vs. Outdoor Use: Aluminum mirror glass sheets can be more prone to damage in outdoor environments where humidity is combined with other harsh conditions like UV rays, pollutants, or saltwater. Indoors, in high-humidity areas like bathrooms, high-quality sheets with moisture-resistant coatings perform better.

Aluminum mirror glass sheets can handle humid conditions with proper protection but may require maintenance or specific treatments to ensure long-lasting performance.

English

English عربى

عربى Español

Español

.jpg?imageView2/2/format/jp2)

-1.jpg?imageView2/2/format/jp2)