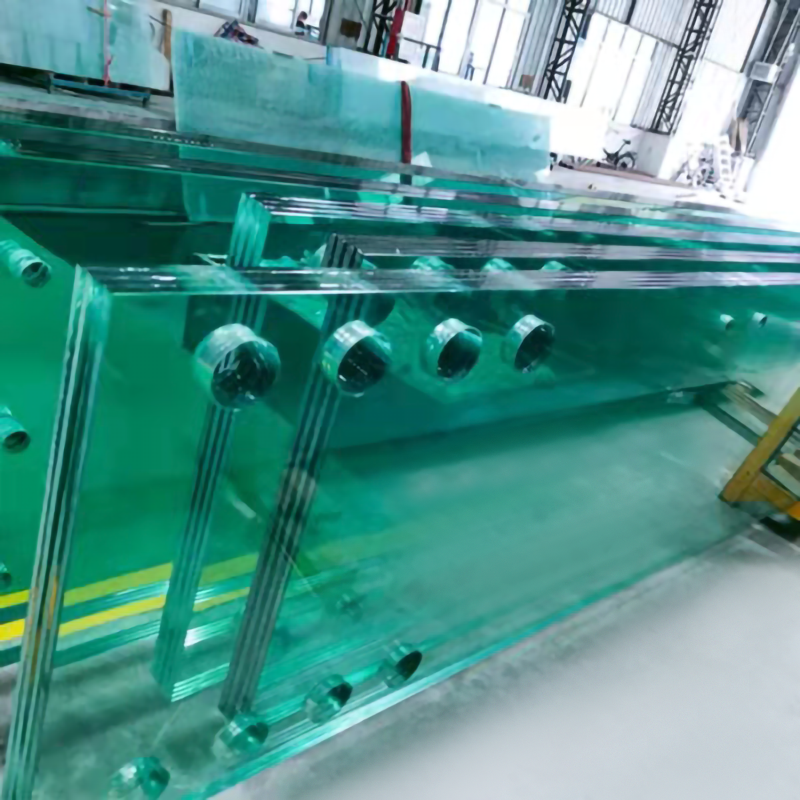

The reason for the self-explosion of tempered glass after tempering is that during the glass manufacturing process, some nickel-containing impurities are mixed in the molten material of raw materials or refractory materials. These impurities are used with each other during the glass melting process to form nickel sulfide crystals.

The tempered glass indicates that the nickel sulfide crystal is in the α phase at high temperatures above 380 °C, and is in the β phase at room temperature. When the nickel sulfide crystal changes from the α phase to the β phase, the volume of the crystal will change by 2-4%, and the diameter of the nickel sulfide crystal that causes the self-explosion of the tempered glass is about 0.2 mm on average. The glass factory needs to go through a slow annealing process when the original glass is formed, and the nickel sulfide crystal basically does not affect the strength of the glass. But things are quite different when tempering glass.

Because the tempered glass adopts a quenching process. Under the action of the cooling wind, the glass cools very fast. When the glass is cooled to room temperature and the structure is completely fixed, the α-phase nickel sulfide crystal has no time to convert into the low-temperature β-phase, but still exists in the high-temperature α-phase state. If nickel sulfide crystals appear in the tensile stress area of tempered glass, as long as the crystal transformation occurs, self-explosion will definitely occur. Due to the uncertainty of the crystal transformation time, the self-explosion of tempered glass at room temperature is also completely uncertain. Detonation processing reduces the probability of self-detonation. The solution to the self-explosion of tempered glass is to homogenize the tempered glass: that is, to reheat the tempered glass to 280-300 ° C, and then keep it for 2-4 hours, so that the tempered glass that is capable of self-explosion bursts in the process.

Homogenization of tempered glass is also called detonation treatment of tempered glass or hot dip treatment of tempered glass. According to the analysis of the glass factory, after strict homogenization treatment, the probability of self-explosion of tempered glass will be greatly reduced. At this time, the tempered glass can be called a real safety glass.

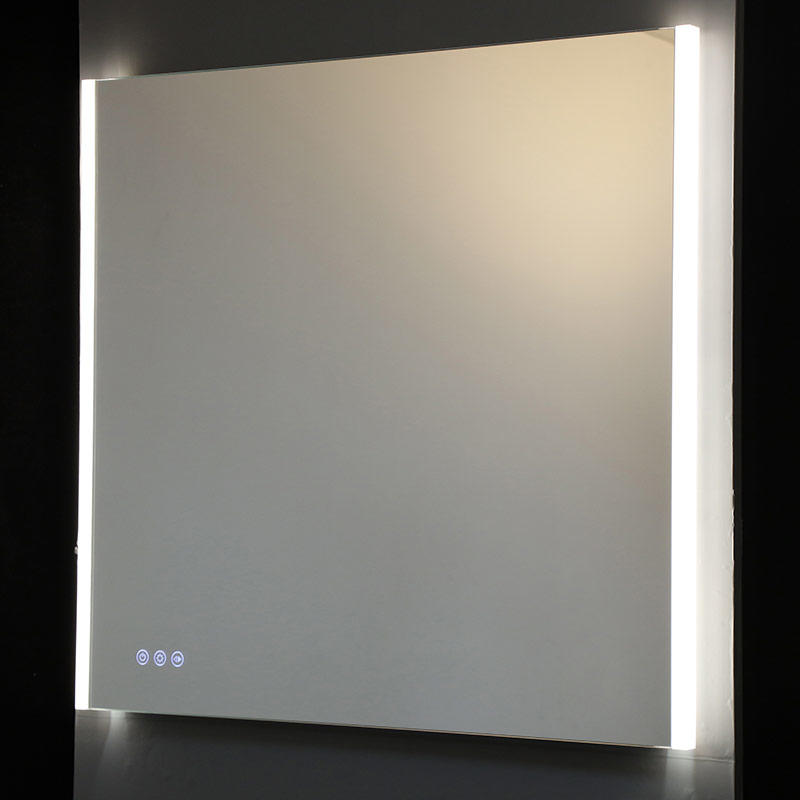

Hangzhou Jinghu Glass Co., Ltd. is one of the most significant glass and mirror manufacturer in China with more than 15 years of experience with a factory covering a space of 12,000sqm. Since its founding, Jinghu glass has been constantly upgrading its factories to be a comprehensive factory that meets world-class standards in producing processed glass and mirror, finished mirror integrating design, research, production, marketing and after-sales services. As OEM Bathroom Mirrors Company and Wholesale Glass Factory, We strictly control the quality in production and after production, to keep the good quality before send to customers. Full ranges of glass and mirror products to meet your one-stop purchasing requirements.

Hangzhou Jinghu Glass Co., Ltd. is one of the most significant glass and mirror manufacturer in China with more than 15 years of experience with a factory covering a space of 12,000sqm. Since its founding, Jinghu glass has been constantly upgrading its factories to be a comprehensive factory that meets world-class standards in producing processed glass and mirror, finished mirror integrating design, research, production, marketing and after-sales services. As OEM Bathroom Mirrors Company and Wholesale Glass Factory, We strictly control the quality in production and after production, to keep the good quality before send to customers. Full ranges of glass and mirror products to meet your one-stop purchasing requirements.

English

English عربى

عربى Español

Español

.jpg?imageView2/2/format/jp2)

-1.jpg?imageView2/2/format/jp2)