In the world of modern architecture and safety design, glass plays an essential role in enhancing both the aesthetic appeal and functionality of structures. However, not all glass is created equal. Among the most widely used types of safety glass are laminated glass and tempered glass. While they both serve as reliable options for enhancing safety and durability, they possess distinct characteristics that make them suitable for different applications. Understanding the difference between laminated glass and tempered glass is key to selecting the right material for your project.

Laminated Glass: A Safety Barrier

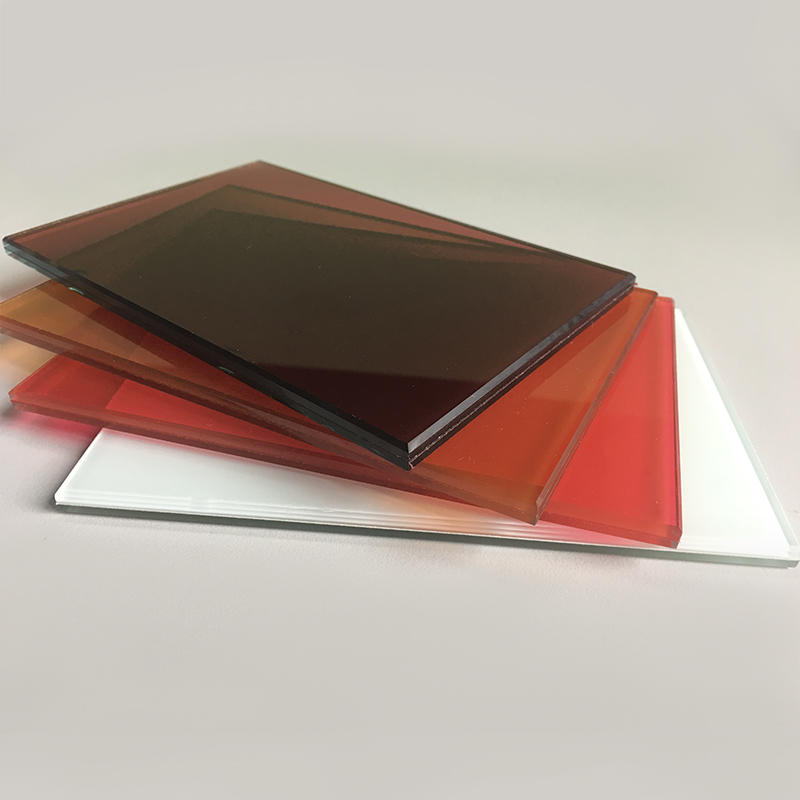

Laminated glass is a composite material that consists of two or more layers of glass fused together with a plastic interlayer, typically made of polyvinyl butyral (PVB). This structure is designed to hold the glass layers together even when shattered, providing an added layer of protection.

One of the most significant advantages of laminated glass is its ability to enhance safety by preventing the glass from breaking into sharp, dangerous shards. In the event of impact, the plastic interlayer absorbs the energy, and the broken glass remains bonded to it, thus reducing the risk of injury. This quality makes laminated glass the preferred choice for applications such as windshields in automobiles, skylights, and glass facades in buildings.

Furthermore, laminated glass offers acoustic insulation, helping to reduce noise pollution. This makes it particularly useful in environments where sound control is critical, such as in high-rise buildings located in noisy urban areas or in recording studios.

Tempered Glass: Strength and Durability

Tempered glass, on the other hand, is a type of safety glass that is strengthened through a specialized heating and cooling process. The glass is first heated to a high temperature, then rapidly cooled, a procedure that puts the outer layers of the glass into compression while the interior remains in tension. This process results in a glass that is significantly stronger than standard glass and more resistant to breakage.

When tempered glass does break, it shatters into small, granular pieces rather than large, jagged shards, reducing the risk of injury. This feature makes tempered glass a highly popular choice for applications where the glass is exposed to high stress, such as in shower doors, tabletops, and automobile side windows. The unique strength of tempered glass also makes it ideal for use in areas that require a high level of durability, such as in security doors and windows.

Key Differences: Safety, Performance, and Applications

While both laminated and tempered glass enhance safety, the fundamental differences lie in their construction and performance characteristics:

Structure and Durability: Laminated glass is designed to remain intact even when damaged, thanks to its plastic interlayer. It is highly effective in preventing injury and maintaining security, even in the event of a break. Tempered glass, by contrast, is strengthened by thermal treatment and is more resistant to impact. However, once broken, it shatters into small, harmless pieces.

Sound Insulation: Laminated glass offers superior soundproofing properties due to the plastic interlayer, making it ideal for use in noise-sensitive environments. Tempered glass does not provide the same level of sound insulation.

Applications: Laminated glass is often used in high-traffic, high-security, and sound-sensitive applications, such as in car windshields, airports, and storefronts. Tempered glass, with its added strength and resistance to breakage, is used in areas that experience heavy wear and tear or where glass is exposed to high levels of stress.

The decision to use laminated glass or tempered glass depends largely on the specific requirements of the project at hand. Laminated glass offers enhanced safety, soundproofing, and security, making it an ideal choice for environments where durability and protection are paramount. Tempered glass, with its superior strength and resistance to breakage, excels in areas where impact resistance and structural integrity are of primary concern.

By understanding the unique properties of each type of glass, you can make an informed decision that best suits the needs of your project, ensuring both safety and longevity.

English

English عربى

عربى Español

Español

.jpg?imageView2/2/format/jp2)

-1.jpg?imageView2/2/format/jp2)