Aluminum mirror glass sheet have gained immense popularity across various industries, from architecture and interior design to automotive and consumer electronics. Their sleek appearance, exceptional durability, and versatility make them a favored choice for countless applications. One of the most significant aspects of these sheets is their surface finishes, which can profoundly influence their aesthetic and functional properties. Let’s explore the surface finishes available for aluminum mirror glass sheets, unraveling their unique attributes and applications.

Polished Finish

The polished finish is synonymous with elegance and clarity. Achieved through meticulous buffing and polishing processes, this surface is exceptionally smooth and highly reflective, offering a near-mirror quality. Polished finishes are often employed in applications where aesthetics reign supreme, such as luxury interiors, decorative panels, and premium signage. Their ability to reflect light effectively also enhances spatial perception, making them an ideal choice for confined spaces.

Brushed Finish

A brushed finish exudes a subtle sophistication. Characterized by fine linear grooves, this finish diffuses light and minimizes glare, creating a softer visual effect. The texture not only adds depth but also masks minor scratches and fingerprints, making it a practical option for high-traffic areas. Brushed aluminum mirror sheets are often found in modern kitchen appliances, elevators, and automotive trim, where style meets resilience.

Matte Finish

For those seeking understated elegance, a matte finish offers a non-reflective surface with a refined appearance. The matte finish reduces glare and provides a muted sheen, making it suitable for environments requiring minimal visual distractions. Ideal for signage, furniture accents, and contemporary design elements, this finish strikes a perfect balance between functionality and subtlety.

Anodized Finish

Anodization not only enhances the appearance but also boosts the durability of aluminum mirror sheets. This electrochemical process forms a protective oxide layer on the surface, available in a spectrum of colors and textures. Anodized finishes resist corrosion, scratches, and UV degradation, making them a preferred choice for outdoor applications, such as building facades, curtain walls, and decorative cladding. The variety of colors allows designers to unleash their creativity while maintaining the inherent advantages of aluminum.

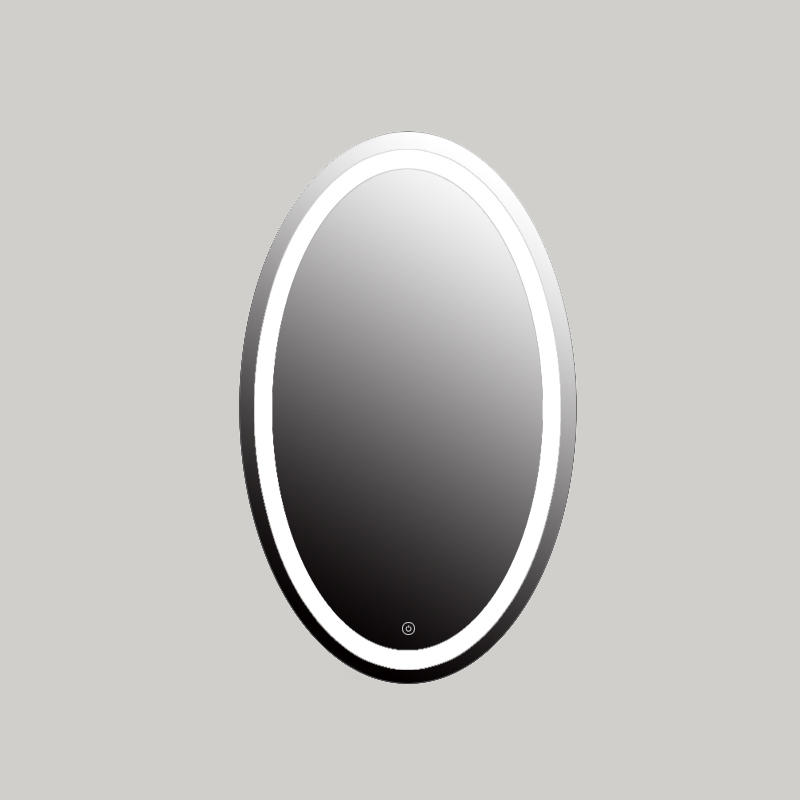

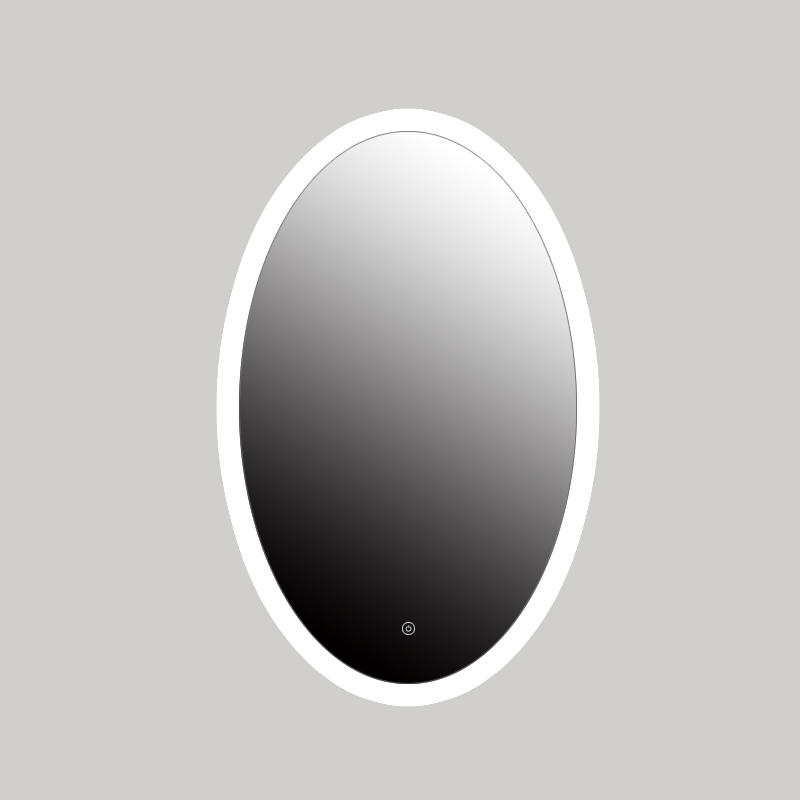

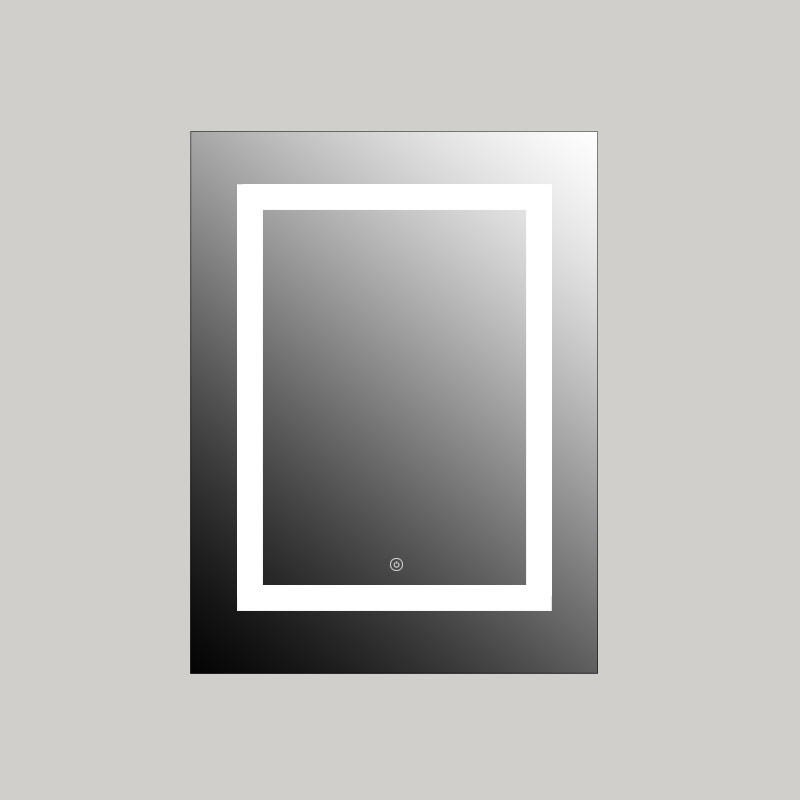

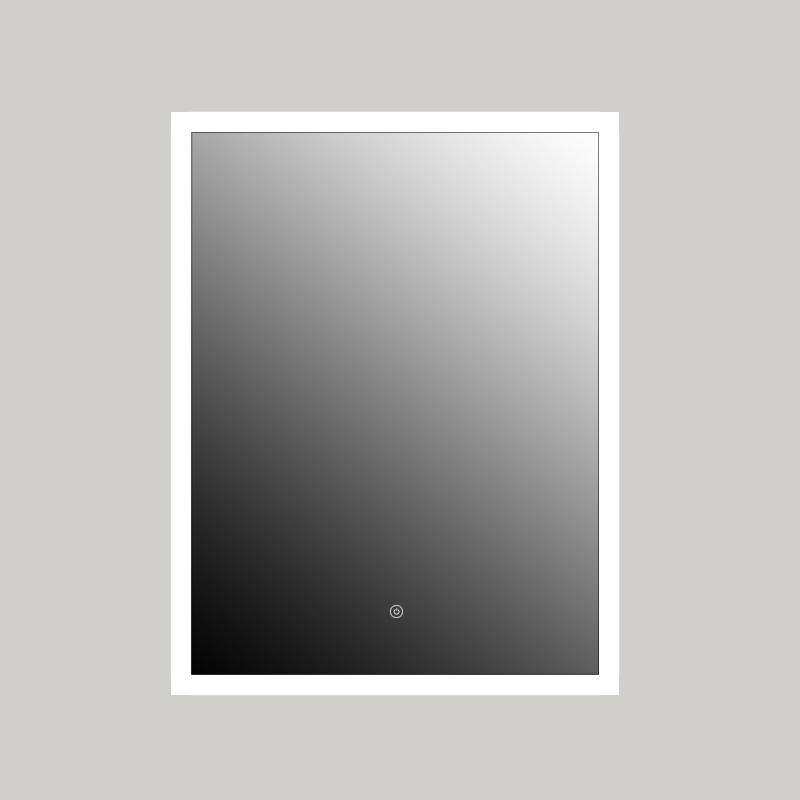

Coated Finish

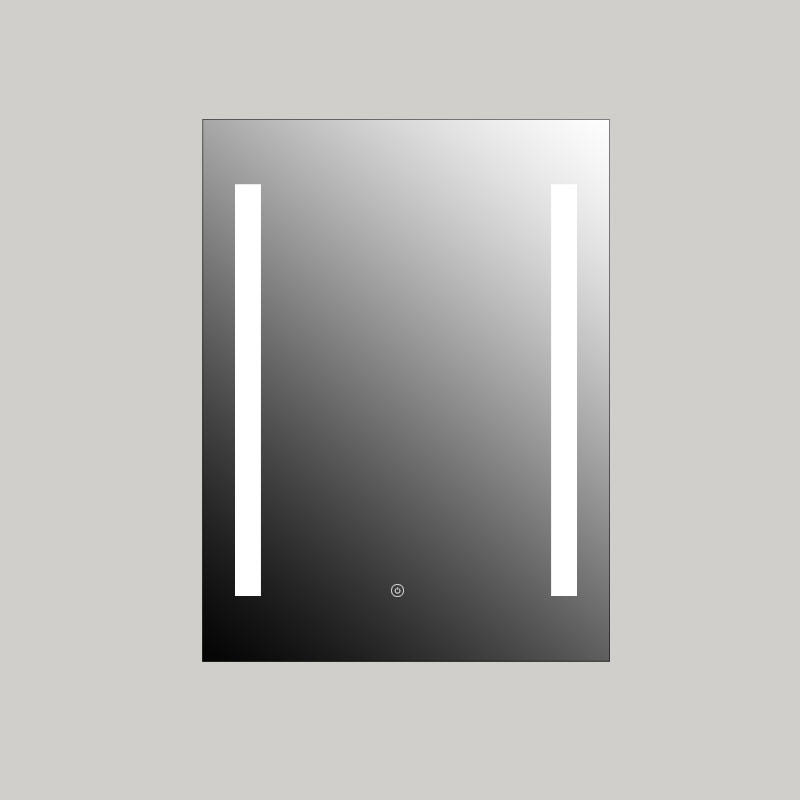

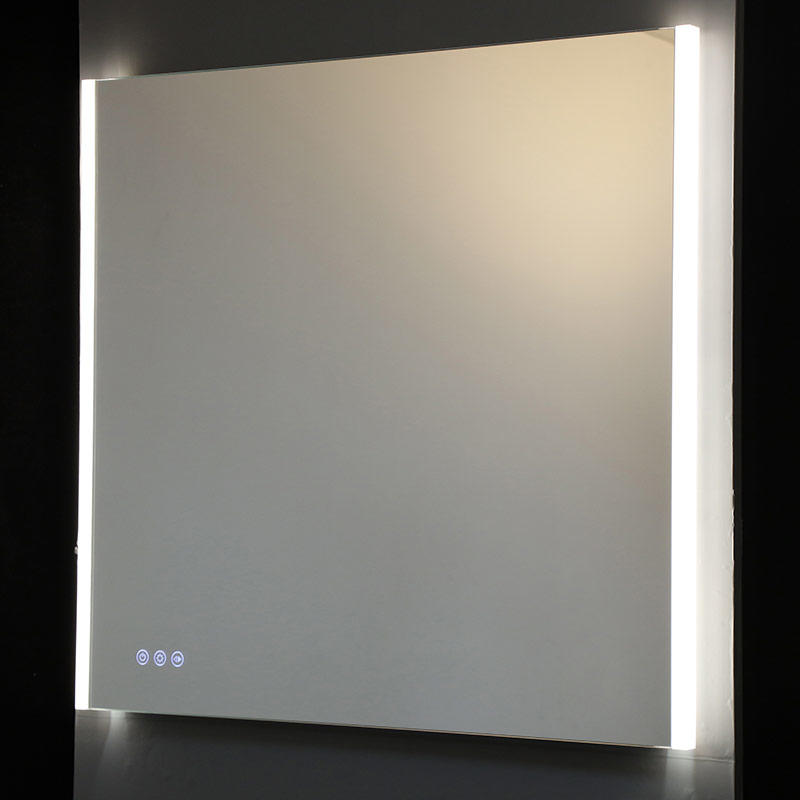

Coated finishes involve the application of specialized coatings that can add unique effects, from anti-fingerprint properties to enhanced scratch resistance. These coatings may also impart additional colors, textures, or gloss levels. Advanced coatings are frequently used in electronic device casings, decorative mirrors, and industrial equipment where both aesthetics and performance are paramount.

Patterned Finish

Patterned finishes introduce artistic flair to aluminum mirror sheets. With options ranging from geometric designs to intricate motifs, patterned surfaces cater to bespoke applications. These finishes are achieved through etching, embossing, or laser engraving, creating tactile and visual interest. They find usage in luxury interiors, high-end retail displays, and architectural installations where uniqueness and personalization are key.

Oxidized Finish

Oxidized finishes emphasize natural beauty while improving corrosion resistance. The controlled oxidation process produces a durable patina that evolves over time, lending character and depth to the surface. This finish is particularly popular in architectural applications, where it complements both modern and rustic aesthetics.

Custom-Tailored Finishes

The ability to customize surface finishes allows manufacturers to cater to specific project requirements. By combining techniques or developing proprietary processes, aluminum mirror sheets can be tailored to achieve desired effects, whether it’s a unique color gradient, an iridescent sheen, or a hybrid texture. Custom finishes often serve niche markets, enabling designers to realize their vision without compromise.

The diverse range of surface finishes available for aluminum mirror glass sheets ensures there is an option to suit every need and aspiration. From polished brilliance to textured sophistication, these finishes offer boundless opportunities for innovation and creativity. Selecting the right finish involves considering both functional demands and aesthetic preferences, ensuring that the final product harmonizes with its intended application. Aluminum mirror glass sheets, with their transformative surface finishes, continue to redefine possibilities across industries, offering a perfect blend of form and function.

English

English عربى

عربى Español

Español

.jpg?imageView2/2/format/jp2)

-1.jpg?imageView2/2/format/jp2)